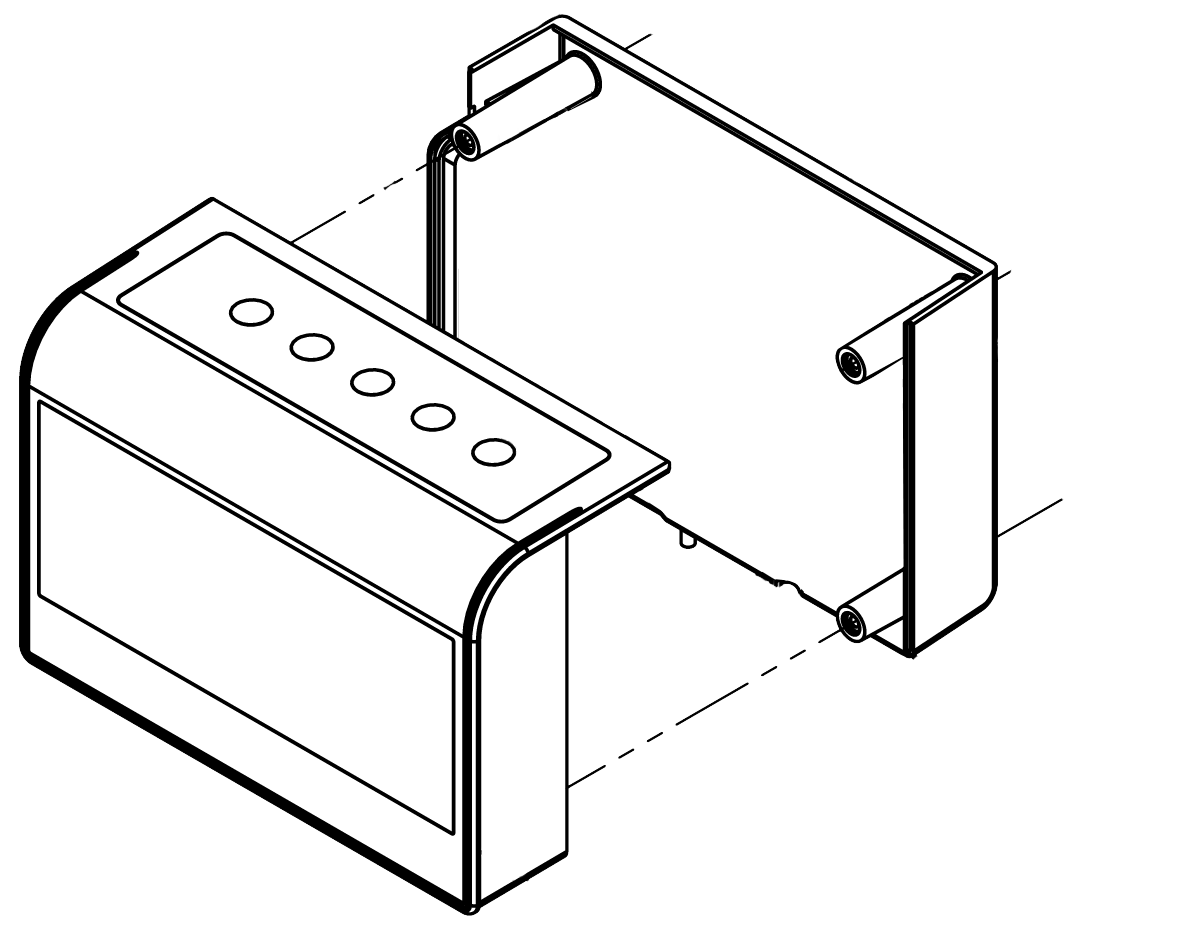

Custom Sign Development and Design

We have worked with designing and producing signs for over 30 years and digital signs for 10+ years. This has given us all the relevant experience both on the hardware side with, e.g., LEDs, LED-drivers, circuitry, processors, memory, buses, contacting, cabling, encapsulation and enclosures, etc. But also on the software side with development of the interntal control software (firmware and configurations), that in turn communicate with cloud solutions, apps or other products.

By letting Sensor Display develop your custom digital sign, you get exactly what you want and have our professional team by your side through the whole process. Apart from our experience and the important know-how, you also get a jump-start by gaining access to existing hardware modules and software libraries that Sensor Display already has in the portfolio.